電驢下載基地 >> 软件资源 >> 行業軟件 >> 《Autodesk注塑成型仿真分析軟件》(Autodesk Simulation MoldFlow Insight Ultimate) 2013 win32/64[壓縮包]

| 《Autodesk注塑成型仿真分析軟件》(Autodesk Simulation MoldFlow Insight Ultimate) 2013 win32/64[壓縮包] | |

|---|---|

| 下載分級 | 软件资源 |

| 資源類別 | 行業軟件 |

| 發布時間 | 2017/7/11 |

| 大 小 | - |

《Autodesk注塑成型仿真分析軟件》(Autodesk Simulation MoldFlow Insight Ultimate) 2013 win32/64[壓縮包] 簡介: 中文名 : Autodesk注塑成型仿真分析軟件 英文名 : Autodesk Simulation MoldFlow Insight Ultimate 資源格式 : 壓縮包 版本 : 2013 win32/64 發行時間 : 2012年 制作發行 : Autodesk Inc. 語言 : 英文 簡介 : 作為歐特克數字樣機解決方案的重要組成部分,Autodesk S

電驢資源下載/磁力鏈接資源下載:

- 下載位址: [www.ed2k.online][Autodesk注塑成型仿真分析軟件].AUTODESK_SIMULATION_MOLDFLOW_INSIGHT_ULTIMATE_2013_WIN32-LND.zip

- 下載位址: [www.ed2k.online][Autodesk注塑成型仿真分析軟件].AUTODESK_SIMULATION_MOLDFLOW_INSIGHT_ULTIMATE_2013_WIN64-LND.zip

全選

"《Autodesk注塑成型仿真分析軟件》(Autodesk Simulation MoldFlow Insight Ultimate) 2013 win32/64[壓縮包]"介紹

中文名: Autodesk注塑成型仿真分析軟件

英文名: Autodesk Simulation MoldFlow Insight Ultimate

資源格式: 壓縮包

版本: 2013 win32/64

發行時間: 2012年

制作發行: Autodesk Inc.

語言: 英文

簡介:

作為歐特克數字樣機解決方案的重要組成部分,Autodesk Simulation Moldflow注塑成型仿真分析軟件是全球公認的注塑行業標准,是值得用戶首選的理想優化工具。利用Autodesk Simulation Moldflow,客戶可以在模具制造之前對產品和模具的設計進行充分的仿真、優化和分析。並通過對材料設計、結構設計、模具設計、工藝設計等的綜合優化,實現高質量和低成本完美的結合,進而實現企業效益與社會效益的完全統一。

近期,歐特克推出了Autodesk Simulation Moldflow 2013,通過專利的長玻纖成型過程中的斷裂情況分析、專利的實時分析技術、結晶性材料在成型過程的結晶度分析和瞬態冷卻和急冷急熱分析(RHCM/RTC)等技術,持續地為客戶提供最新的成型模擬技術,幫助客戶顯著降低大模型的分析時間。

迅速、准確和靈活的注塑成型仿真工具可幫助優化塑料零件和注塑模具。

Autodesk® Simulation Moldflow® 注塑成型仿真軟件通過精確地預測注塑成型過程,提供了能夠幫助制造商驗證和優化塑料零件和注塑模具的工具。全球的公司都在使用Autodesk® Simulation Moldflow® Adviser 和 Autodesk® Simulation Moldflow® Insight 軟件來減少對高成本物理樣機的需求,減少潛在的制造缺陷,更快地向市場推出創新的產品。

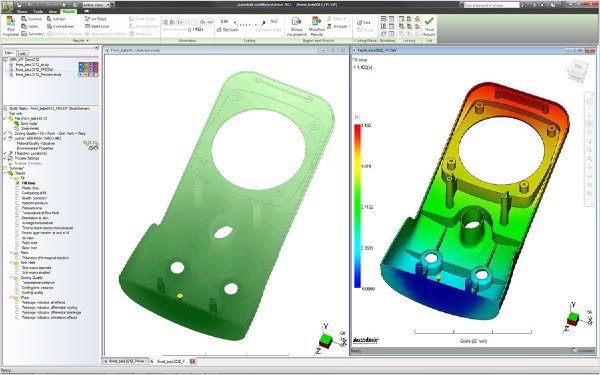

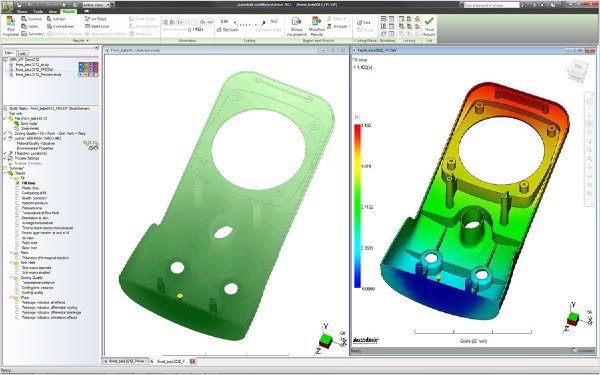

Autodesk® Simulation Moldflow® 軟件提供的仿真工具可用於設計注塑模具、塑料零件及驗證和優化注塑成型的設計流程。該軟件能夠為設計人員、模具制作人員、工程師提供指導,通過仿真的設置和結果的闡述來展示壁厚、澆口位置、材質、幾何結構的變化如何影響產品的可制造性,無論是對於熱固性材料還是熱塑性材料。Autodesk Simulation Moldflow 的主要特性包括:

多 CAD 導入

對於所有 Autodesk® Simulation 軟件而言,不論三維 CAD 數據的來源何種CAD系統,Simulation Moldflow 都支持您評估多種可能的塑料零件設計方案。購買了 Simulation Moldflow 2013 許可的 Autodesk® Subscription 客戶可將 Rhino、Alias 和 NX 等CAD系統所生成文件直接導入 Simulation Moldflow。同時,還可以使用2013的新功能 — Autodesk® Vault 軟件 來管理和跟蹤這些文件。

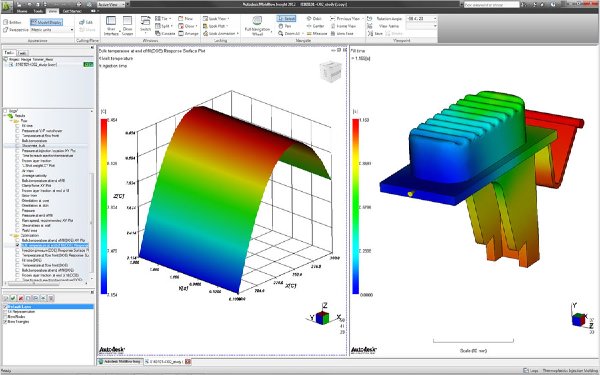

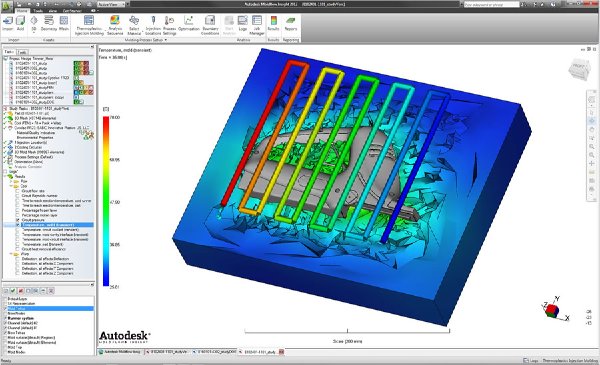

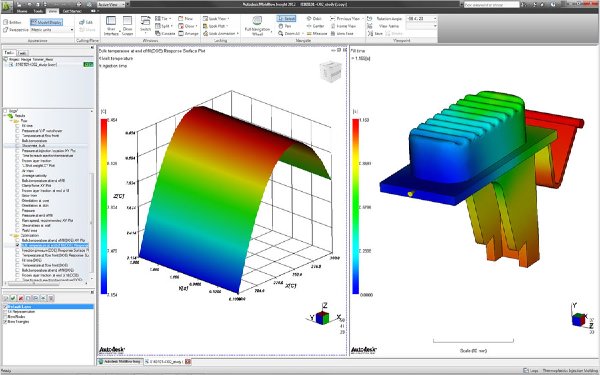

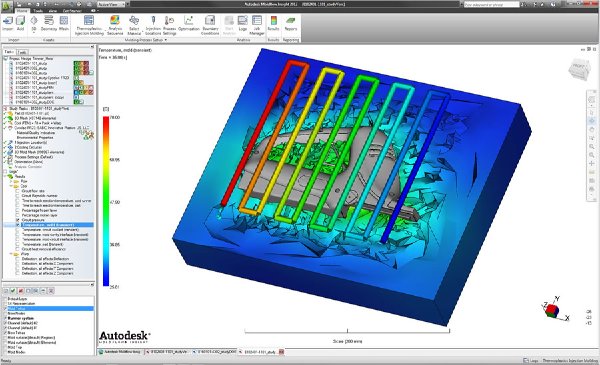

注塑模具的瞬時加熱和冷卻(急冷急熱)

在注塑成型周期中,確定模具的溫度變化。預測從生產開始到模具達到穩定溫度所需要的周期數量。Simulation Moldflow 2013 支持快速溫度循環並增強了模具的加熱單元。

塑料零件設計中的纖維取向

更加精確地預測短玻纖和長玻纖的取向 — 包括長纖維的斷裂,這是決定塑料零件整體性能、形狀、強度與重量的關鍵。然後可將產生的材質屬性傳遞給 Autodesk Simulation,以進行精確的機械性能分析。您可借助 Simulation Moldflow 2013 來預測反應成型產品的纖維取向。

設計優化

借助 Autodesk® Simulation Moldflow® Insight 軟件,實驗設計 (DOE) 能力擴展至所有網格類型、成型過程和仿真工具,幫助您更好地優化注塑成型零件的設計與制造。

收縮和翹曲仿真

評估塑料零件和注塑模具的設計,以便根據材質的具體等級和工藝參數控制產品的收縮和翹曲。您可精確地輸出補償模型,以便進行模具或其它幾何的調整。

Autodesk Moldflow: Thermoset Flow Simulation

熱固性塑料流動仿真

對熱固性塑料注塑成型、RIM/SRIM、樹脂傳遞成型以及橡膠復合注塑成型進行仿真。

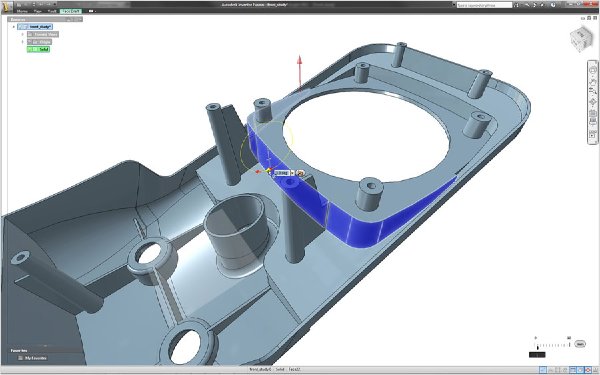

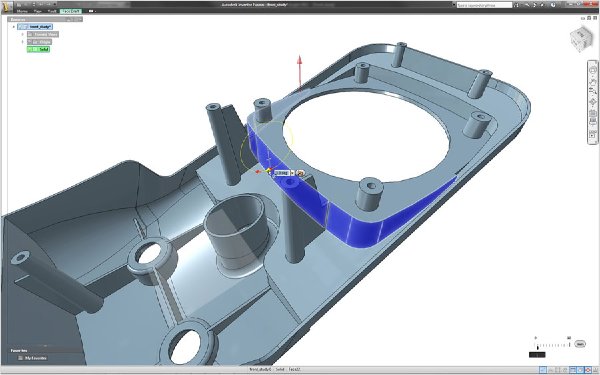

Autodesk Moldflow: Geometry Modification

幾何調整

借助 Autodesk Simulation Moldflow,您可以使用 Autodesk® Inventor® Fusion 軟件來更加迅速、輕松地調整和簡化幾何體,以便快速的優化塑料零件設計和可制造性及質量。

Autodesk Moldflow: Specialized Molding Processes

特殊的成型工藝

對廣泛的注塑成型工藝和特殊的成型工藝應用進行仿真。

Autodesk Moldflow: CAD Interoperability Tools

CAD 互操作工具

使用工具進行本地的CAD模型轉換和優化。

Autodesk Moldflow: Material Data

材質數據

利用 8,700 多種具有精確的材質數據的材料來提高仿真精度。Autodesk® Simulation Moldflow® 塑料實驗室提供了額外的材料測試服務、專業的數據擬合服務以及豐富的材質數據庫。

Autodesk Moldflow: CAE Data Exchange

CAE 數據交換

使用工具與結構仿真軟件進行數據交換,驗證和優化塑料零件的設計。可與 Autodesk® Simulation Multiphysics、ANSYS® 和 Abaqus®結構仿真軟件交換CAE數據,以此根據成型後產品的材質屬性來預測塑料零件的實際性能。

Autodesk Moldflow: Autodesk Moldflow Communicator

Autodesk Simulation Moldflow Communicator

使用免費的 Autodesk® Simulation Moldflow® Communicator 軟件與生產人員、采購工程師、供應商和客戶加強協作。Simulation Moldflow Communicator 結果浏覽器支持您從 Autodesk Simulation Moldflow 軟件導出結果,以便利益相關方可以輕松查看、量化和比較仿真結果。

系統需求

32 位:Microsoft® Windows® 7 Professional、Enterprise 或 Ultimate 版;Microsoft® Windows® XP Professional 版(SP3)

64 位:Windows 7 Professional、Enterprise 或 Ultimate;Windows XP Professional(SP2)

1 GHz 的 CPU 速度(或更快)

2 GB 內存(或更大)

1GB 或更大的虛擬內存/交換空間

4 GB 或更多可用磁盤空間(安裝需要 750 MB 可用磁盤空間)

配有 512 MB DRAM 或更高顯存的 OpenGL® 顯卡

支持 24 位色以及 1,280 x 1,024 或更高分辨率

Microsoft® Internet Explorer® 7 或更高版本的 web 浏覽器

以太網卡

DVD-ROM 驅動器*

兼容微軟鼠標的指點設備

Adobe® Flash® Player 9

用於網絡下載的互聯網連接

資源更新列表

http://www.VeryCD.com/i/5190747/create/fol...postTime

Autodesk® Simulation Moldflow® plastic injection molding simulation software provides tools that help manufacturers validate and optimize the design of plastic parts and injection molds by accurately predicting the plastic injection molding process. Companies worldwide use Autodesk® Simulation Moldflow® Adviser and Autodesk® Simulation Moldflow® Insight software to help reduce the need for costly physical prototypes, avoid potential manufacturing defects, and get innovative products to market faster.

Autodesk® Simulation Moldflow® software provides simulation tools for injection mold design, plastic part design, and validating and optimizing the injection molding design process. The software guides designers, mold makers, and engineers through simulation setup and results interpretation to show how changes to wall thickness, gate location, material, and geometry affect manufacturability for thermoset and thermoplastic materials. Key features of Autodesk Simulation Moldflow include:

Multi-CAD Import

As with all Autodesk® Simulation software, Simulation Moldflow enables you to evaluate a range of potential plastic part designs regardless of where the 3D CAD data comes from. Autodesk® Subscription customers who purchase a license of Simulation Moldflow 2013 can import Rhino, Alias, and NX files directly into Simulation Moldflow. The files can then be managed and tracked using Autodesk® Vault software, also a new 2013 capability.

Autodesk Moldflow: Transient Cooling of Plastic Injection Molds

Transient Heating & Cooling of Plastic Injection Molds

Determine temperature variation in an injection mold during a plastic injection molding cycle. Predict the number of cycles required from production startup until the mold reaches a stable temperature. Simulation Moldflow 2013 includes support for rapid temperature cycling and enhanced mold heating elements.

Autodesk Moldflow: Fiber Orientation in Plastic Part Designs

Fiber Orientation in Plastic Part Designs

More accurately predict the orientation of short and long glass fibers—including long fiber breakage—which is critical to the overall performance, shape, strength, and weight of reinforced plastic parts. The resulting material properties can then be sent to Autodesk Simulation for accurate mechanical performance analysis. With Simulation Moldflow 2013, you can predict fiber orientation for reactive molding products.

Autodesk Moldflow: Design Optimization

Design Optimization

With Autodesk® Simulation Moldflow® Insight software, the design of experiments (DOE) capabilities are expanded to all mesh types, molding processes, and simulation tools—helping to better optimize the design and manufacturing of injection-molded plastic parts.

Autodesk Moldflow: Shrinkage and Warpage Simulation

Shrinkage and Warpage Simulation

Evaluate plastic part and injection mold designs to help control shrinkage and warpage based on grade-specific materials and processing parameters. You can output accurately compensated models for tooling or further geometry modification.

Autodesk Moldflow: Thermoset Flow Simulation

Thermoset Flow Simulation

Simulate thermoset injection molding, RIM/SRIM, resin transfer molding, and rubber compound injection molding.

Autodesk Moldflow: Geometry Modification

Geometry Modification

With Autodesk Simulation Moldflow, you can use Autodesk® Inventor® Fusion software to modify or simplify geometry more quickly and easily, helping to optimize plastic part designs for manufacturability and quality as quickly as possible.

Autodesk Moldflow: Specialized Molding Processes

Specialized Molding Processes

Simulate a wide range of plastic injection molding processes and specialized process applications.

Autodesk Moldflow: CAD Interoperability Tools

CAD Interoperability Tools

Use tools for native CAD model translation and optimization.

Autodesk Moldflow: Material Data

Material Data

Improve simulation accuracy with precise material data on more than 8,700 grade specific plastics. Get additional materials tested, expert data-fitting services, and extensive material databases with the Autodesk® Simulation Moldflow® Plastics Labs.

Autodesk Moldflow: CAE Data Exchange

CAE Data Exchange

Validate and optimize plastic part designs using tools to exchange data with structural simulation software. CAE data exchange is available with Autodesk® Simulation Multiphysics, ANSYS®, and Abaqus® structural simulation software to help predict the real-life behavior of plastic parts by using as-manufactured material properties.

Autodesk Moldflow: Autodesk Moldflow Communicator

Autodesk Simulation Moldflow Communicator

Collaborate with manufacturing personnel, procurement engineers, suppliers, and external customers using the free* Autodesk® Simulation Moldflow® Communicator software. The Simulation Moldflow Communicator results viewer enables you to export results from Autodesk Simulation Moldflow software, so stakeholders can more easily visualize, quantify, and compare simulation results.

代碼

英文名: Autodesk Simulation MoldFlow Insight Ultimate

資源格式: 壓縮包

版本: 2013 win32/64

發行時間: 2012年

制作發行: Autodesk Inc.

語言: 英文

簡介:

作為歐特克數字樣機解決方案的重要組成部分,Autodesk Simulation Moldflow注塑成型仿真分析軟件是全球公認的注塑行業標准,是值得用戶首選的理想優化工具。利用Autodesk Simulation Moldflow,客戶可以在模具制造之前對產品和模具的設計進行充分的仿真、優化和分析。並通過對材料設計、結構設計、模具設計、工藝設計等的綜合優化,實現高質量和低成本完美的結合,進而實現企業效益與社會效益的完全統一。

近期,歐特克推出了Autodesk Simulation Moldflow 2013,通過專利的長玻纖成型過程中的斷裂情況分析、專利的實時分析技術、結晶性材料在成型過程的結晶度分析和瞬態冷卻和急冷急熱分析(RHCM/RTC)等技術,持續地為客戶提供最新的成型模擬技術,幫助客戶顯著降低大模型的分析時間。

迅速、准確和靈活的注塑成型仿真工具可幫助優化塑料零件和注塑模具。

Autodesk® Simulation Moldflow® 注塑成型仿真軟件通過精確地預測注塑成型過程,提供了能夠幫助制造商驗證和優化塑料零件和注塑模具的工具。全球的公司都在使用Autodesk® Simulation Moldflow® Adviser 和 Autodesk® Simulation Moldflow® Insight 軟件來減少對高成本物理樣機的需求,減少潛在的制造缺陷,更快地向市場推出創新的產品。

Autodesk® Simulation Moldflow® 軟件提供的仿真工具可用於設計注塑模具、塑料零件及驗證和優化注塑成型的設計流程。該軟件能夠為設計人員、模具制作人員、工程師提供指導,通過仿真的設置和結果的闡述來展示壁厚、澆口位置、材質、幾何結構的變化如何影響產品的可制造性,無論是對於熱固性材料還是熱塑性材料。Autodesk Simulation Moldflow 的主要特性包括:

多 CAD 導入

對於所有 Autodesk® Simulation 軟件而言,不論三維 CAD 數據的來源何種CAD系統,Simulation Moldflow 都支持您評估多種可能的塑料零件設計方案。購買了 Simulation Moldflow 2013 許可的 Autodesk® Subscription 客戶可將 Rhino、Alias 和 NX 等CAD系統所生成文件直接導入 Simulation Moldflow。同時,還可以使用2013的新功能 — Autodesk® Vault 軟件 來管理和跟蹤這些文件。

注塑模具的瞬時加熱和冷卻(急冷急熱)

在注塑成型周期中,確定模具的溫度變化。預測從生產開始到模具達到穩定溫度所需要的周期數量。Simulation Moldflow 2013 支持快速溫度循環並增強了模具的加熱單元。

塑料零件設計中的纖維取向

更加精確地預測短玻纖和長玻纖的取向 — 包括長纖維的斷裂,這是決定塑料零件整體性能、形狀、強度與重量的關鍵。然後可將產生的材質屬性傳遞給 Autodesk Simulation,以進行精確的機械性能分析。您可借助 Simulation Moldflow 2013 來預測反應成型產品的纖維取向。

設計優化

借助 Autodesk® Simulation Moldflow® Insight 軟件,實驗設計 (DOE) 能力擴展至所有網格類型、成型過程和仿真工具,幫助您更好地優化注塑成型零件的設計與制造。

收縮和翹曲仿真

評估塑料零件和注塑模具的設計,以便根據材質的具體等級和工藝參數控制產品的收縮和翹曲。您可精確地輸出補償模型,以便進行模具或其它幾何的調整。

Autodesk Moldflow: Thermoset Flow Simulation

熱固性塑料流動仿真

對熱固性塑料注塑成型、RIM/SRIM、樹脂傳遞成型以及橡膠復合注塑成型進行仿真。

Autodesk Moldflow: Geometry Modification

幾何調整

借助 Autodesk Simulation Moldflow,您可以使用 Autodesk® Inventor® Fusion 軟件來更加迅速、輕松地調整和簡化幾何體,以便快速的優化塑料零件設計和可制造性及質量。

Autodesk Moldflow: Specialized Molding Processes

特殊的成型工藝

對廣泛的注塑成型工藝和特殊的成型工藝應用進行仿真。

Autodesk Moldflow: CAD Interoperability Tools

CAD 互操作工具

使用工具進行本地的CAD模型轉換和優化。

Autodesk Moldflow: Material Data

材質數據

利用 8,700 多種具有精確的材質數據的材料來提高仿真精度。Autodesk® Simulation Moldflow® 塑料實驗室提供了額外的材料測試服務、專業的數據擬合服務以及豐富的材質數據庫。

Autodesk Moldflow: CAE Data Exchange

CAE 數據交換

使用工具與結構仿真軟件進行數據交換,驗證和優化塑料零件的設計。可與 Autodesk® Simulation Multiphysics、ANSYS® 和 Abaqus®結構仿真軟件交換CAE數據,以此根據成型後產品的材質屬性來預測塑料零件的實際性能。

Autodesk Moldflow: Autodesk Moldflow Communicator

Autodesk Simulation Moldflow Communicator

使用免費的 Autodesk® Simulation Moldflow® Communicator 軟件與生產人員、采購工程師、供應商和客戶加強協作。Simulation Moldflow Communicator 結果浏覽器支持您從 Autodesk Simulation Moldflow 軟件導出結果,以便利益相關方可以輕松查看、量化和比較仿真結果。

系統需求

32 位:Microsoft® Windows® 7 Professional、Enterprise 或 Ultimate 版;Microsoft® Windows® XP Professional 版(SP3)

64 位:Windows 7 Professional、Enterprise 或 Ultimate;Windows XP Professional(SP2)

1 GHz 的 CPU 速度(或更快)

2 GB 內存(或更大)

1GB 或更大的虛擬內存/交換空間

4 GB 或更多可用磁盤空間(安裝需要 750 MB 可用磁盤空間)

配有 512 MB DRAM 或更高顯存的 OpenGL® 顯卡

支持 24 位色以及 1,280 x 1,024 或更高分辨率

Microsoft® Internet Explorer® 7 或更高版本的 web 浏覽器

以太網卡

DVD-ROM 驅動器*

兼容微軟鼠標的指點設備

Adobe® Flash® Player 9

用於網絡下載的互聯網連接

資源更新列表

http://www.VeryCD.com/i/5190747/create/fol...postTime

Autodesk® Simulation Moldflow® plastic injection molding simulation software provides tools that help manufacturers validate and optimize the design of plastic parts and injection molds by accurately predicting the plastic injection molding process. Companies worldwide use Autodesk® Simulation Moldflow® Adviser and Autodesk® Simulation Moldflow® Insight software to help reduce the need for costly physical prototypes, avoid potential manufacturing defects, and get innovative products to market faster.

Autodesk® Simulation Moldflow® software provides simulation tools for injection mold design, plastic part design, and validating and optimizing the injection molding design process. The software guides designers, mold makers, and engineers through simulation setup and results interpretation to show how changes to wall thickness, gate location, material, and geometry affect manufacturability for thermoset and thermoplastic materials. Key features of Autodesk Simulation Moldflow include:

Multi-CAD Import

As with all Autodesk® Simulation software, Simulation Moldflow enables you to evaluate a range of potential plastic part designs regardless of where the 3D CAD data comes from. Autodesk® Subscription customers who purchase a license of Simulation Moldflow 2013 can import Rhino, Alias, and NX files directly into Simulation Moldflow. The files can then be managed and tracked using Autodesk® Vault software, also a new 2013 capability.

Autodesk Moldflow: Transient Cooling of Plastic Injection Molds

Transient Heating & Cooling of Plastic Injection Molds

Determine temperature variation in an injection mold during a plastic injection molding cycle. Predict the number of cycles required from production startup until the mold reaches a stable temperature. Simulation Moldflow 2013 includes support for rapid temperature cycling and enhanced mold heating elements.

Autodesk Moldflow: Fiber Orientation in Plastic Part Designs

Fiber Orientation in Plastic Part Designs

More accurately predict the orientation of short and long glass fibers—including long fiber breakage—which is critical to the overall performance, shape, strength, and weight of reinforced plastic parts. The resulting material properties can then be sent to Autodesk Simulation for accurate mechanical performance analysis. With Simulation Moldflow 2013, you can predict fiber orientation for reactive molding products.

Autodesk Moldflow: Design Optimization

Design Optimization

With Autodesk® Simulation Moldflow® Insight software, the design of experiments (DOE) capabilities are expanded to all mesh types, molding processes, and simulation tools—helping to better optimize the design and manufacturing of injection-molded plastic parts.

Autodesk Moldflow: Shrinkage and Warpage Simulation

Shrinkage and Warpage Simulation

Evaluate plastic part and injection mold designs to help control shrinkage and warpage based on grade-specific materials and processing parameters. You can output accurately compensated models for tooling or further geometry modification.

Autodesk Moldflow: Thermoset Flow Simulation

Thermoset Flow Simulation

Simulate thermoset injection molding, RIM/SRIM, resin transfer molding, and rubber compound injection molding.

Autodesk Moldflow: Geometry Modification

Geometry Modification

With Autodesk Simulation Moldflow, you can use Autodesk® Inventor® Fusion software to modify or simplify geometry more quickly and easily, helping to optimize plastic part designs for manufacturability and quality as quickly as possible.

Autodesk Moldflow: Specialized Molding Processes

Specialized Molding Processes

Simulate a wide range of plastic injection molding processes and specialized process applications.

Autodesk Moldflow: CAD Interoperability Tools

CAD Interoperability Tools

Use tools for native CAD model translation and optimization.

Autodesk Moldflow: Material Data

Material Data

Improve simulation accuracy with precise material data on more than 8,700 grade specific plastics. Get additional materials tested, expert data-fitting services, and extensive material databases with the Autodesk® Simulation Moldflow® Plastics Labs.

Autodesk Moldflow: CAE Data Exchange

CAE Data Exchange

Validate and optimize plastic part designs using tools to exchange data with structural simulation software. CAE data exchange is available with Autodesk® Simulation Multiphysics, ANSYS®, and Abaqus® structural simulation software to help predict the real-life behavior of plastic parts by using as-manufactured material properties.

Autodesk Moldflow: Autodesk Moldflow Communicator

Autodesk Simulation Moldflow Communicator

Collaborate with manufacturing personnel, procurement engineers, suppliers, and external customers using the free* Autodesk® Simulation Moldflow® Communicator software. The Simulation Moldflow Communicator results viewer enables you to export results from Autodesk Simulation Moldflow software, so stakeholders can more easily visualize, quantify, and compare simulation results.

代碼

Ü Ü

Ü ß ß þÜ °

° Üþß ß²Ü± °

° Ü²ß ß²ÛÜÜ ±

± ÜÜÜÛ²ß Ü² °Üܲ Ü ÞÛÛÛÛÛ۲ܰ

ÜÜܲÜÜÛÛÛÛÛÛ²Ý ÜÜÛÛÝ ÜÜÜÛÛÛÛ ÜÛ²ÛÜ ÛÛÛÛÛÛÛÛÛÛÛÜÜÜ

ÜÝ ß²²²²ÛÛÛÛÛ²² ÜÜÛÛÛÛÛÛÛÜ ÞÛÛÛÛÛÝ ÜܲÛÛÛÛÛÛßß²ÛÛÛÛÛÛÛÛÛ²ß ÞÜ°

ß²²²Ûßß ß Þ²²ÛÛÛÛÛ²²Ý ÞÛÛÛÛÛ۲߲²ÜÛÛÛÛÛ Þ²²²ÛÛÛÛÛÝ ²ÛÛÛÛÛ²²Û ß ßßÛ²²²ß

²² ° Û²ÛÛÛÛ²²² ÛÛÛÛÛÛÝ ß²ÛÛÛÛ² ÞÛ²ÛÛÛÛÛÛÝ ÞÛÛÛÛ²²²Ý ° ²²

²Ý ° °°°° ÞÛÛÛÛÛ²²² Û²ÛÛÛ²Ý ÞÛÛÛÛ² ÜÛÛÛÛÛÛÛÛÛ ÜÛÛÛÛÛÛÛ²Ý °°°° ° Þ²

²Ý °° ÞÛÛÛÛÛÛ²²Ý ßßÛÛÛ²²² ÜÛÛÛÛÛ²Ý ßÛÛÛÛÛÛÛÝ ßßßÛÛÛÛÛÛÛÝ °° Þ²

²Ý ° Þ²ÛÛÛÛÛ²²² ßß²²Ý ßßÛ²²² ß²ÛÛÛß °ßßÛÛÛÛ ° Þ²

Û²Ü ÛÛÛÛÛÛÛÛ²²ÛÜ ßß ß²²Ü ßß ßß²Ü Ü²Û

ß²Ûßßßß ß Ü²ßß° ßßß²²Û²Ü ß ßß ß²ß ß ß²²Ûßß ß ß ßßßß ß ß ßßßßÛ²ß

Þ ² ßß²Ü Þ² Ý

± ßþÜ Üß cH!

° ß þ Ü þß

ÉÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ»

º MOLDFLOW INSIGHT ULTIMATE 2013 WIN64 (c) AUTODESK º

ȳÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍͳ¼

ÀÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

Packaged @: 11/13/2012 54 x 5.24 MB :..Number of Disks

Cracker...: Team LND Winall :.Operating System

Packager..: Team LND Serial :Serial/Protection

Supplier..: Team LND

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄ¿

Product Description ³

ÖÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

º

º http://usa.autodesk.com/moldflow/

º

ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ͸

Install Description ³

ÖÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

º

º Unpack

º LEGEND dir

º Enjoy

º

ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ͸

Legendary News & Info ³

ÖÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

º

º Legends Never Die is dedicated to bring you quality software. Our primary

º focus is software in CAD/CAM/CAE/FEA. Your support is needed, so keep

º emailing us information about the software you might be able to

º contribute.

º

º We are also looking for good crackers, especially those that can crack

º WindowsNT programs. Keywords are FlexLM, Hasp, Sentinel. If you feel up

º for the job contact us on the email address below.

º

º Legends Never Die is a Non-profit organization. We dont make or give money

º for software.

º With Respect -DREAMTEAM 2002

º

ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ͸

Legendary Application Info ³

ÖÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

º

º If you wish to be a part of the team and can provide one of the following

º services then please get in touch with us at the address below, at this

º point we are only taking in the positions that are listed below but if

º you think you have something to offer us that we have not thought of, of

º course you can mail us about it.

º

º *) If you work for an Internet Service Provider or can provide services.

º *) If you can supply hardware to our cause.

º *) If you work at a software company or have access to new software.

º *) If you have the capability to remove software protection.

º

º Assholes & Lamers need not apply.

º

º *** WE DO NOT MAIL OUR RELEASES, OR PARTS OF OUR RELEASES.

º

º Contacting Legends Never Die:

º Email: [email protected]

º Irc : Closed

º

ÈÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍÍ͸

Layout: Phr33phal ³

ÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÄÙ

- 上一頁:《生物工程數據可視化工具》(Visage Imaging Amira)v5.4.3[壓縮包]

- 下一頁:《Autodesk Moldflow產品系列數據鏈接工具》(Autodesk Moldflow Design Link)2013[壓縮包]

相關資源:

- [應用軟件]《ADOBE CS2 全系列的注冊機》,應用軟件、資源下載

- [多媒體類]《DJ 混合軟件》(UltraMixer Professional)v3.0.0.0[壓縮包]

- [應用軟件]《PDF制作編輯審閱軟件》(PDF Pro 10)更新v10.4.0000/含注冊機[壓縮包]

- [應用軟件]PS教程:設計自己的炫酷簽名毛筆字 ps基礎 ps入門 上【51rgb出品】

- [多媒體類]《高級建模軟件Modo301》(Luxology Modo 301)

- [應用軟件]Advanced NTFS Undelete

- [行業軟件]《組織結構規劃解決方案》(OrgPublisher Premier)更新v10.1.3059/含注冊機[壓縮包]

- [系統工具]《企業數據備份還原軟件》(GFI Backup 2010)v3.1.20100713/含注冊機[壓縮包]

- [行業軟件]《Accelrys研發業務智能平台》(Accelrys.Pipline.Pilot)7.01[光盤鏡像],行業軟件、資源下載

- [軟件綜合]《如師通語言學習軟件(羅塞塔石碑)》(Rosetta Stone) v3.4.5 英語/日語/法語/德語/韓語/俄語/西班牙語/意大利語/阿拉伯語/葡萄牙語/漢語

- [文學圖書]《藝術交往論》(黃鳴奮)掃描版[PDF]

- [人文社科]《龍:一種未明的動物》(馬小星)掃描版[PDF]

- [學習材料]《中國書法美學》(金學智)掃描版[PDF]資料下載

- [教育科技]《動物世界的秘密-魚是如何浮水游泳》(李廣華

- [多媒體類]《多功能刻錄軟件》(AVS Disc Creator)v5.0.3.517[壓縮包]

- [電腦基礎]Auto CAD 2010 從入門與精通視頻教程

- [光盤游戲]《萌學戀愛》(Moegaku)[光盤鏡像]

- [應用軟件]Parallels Desktop 10 for Mac

- [生活圖書]《百歲醫生教我的生機健康法》(JOUSHIKI YABURI NO CHOU KENKOU KAKUMEI)([日]松田麻美子 MAMIKO MATSUDA)文字版,2007年6月第一版[PDF]

- [經濟管理]《賺錢金點子大全集 超值金版》掃描版[PDF]

- 《Siemens Sinutrain數控系統教育/培訓軟件》(Siemens Sinutrain v6.3 Edition 3 MULTiLANGUAGE)[Bin]

- 《2011IT產品參數速查》(2011IT產品參數速查)2001[安裝包]

- 《終極化學生物設計軟件》(ChemBioOffice WorkGroup Ultra 2009 v11.0.2)[光盤鏡像],行業軟件、資源下載

- 《電子工作平台》(ELECTRONICS WORKBENCH(EWB))5.12[安裝包]

- 《超級渲染器》(CEBAS final Render for 3DSMax 2009-2012)更新R3.5 SE SP6/Win32|64/含破解[壓縮包]

- 《Maxwell 渲染器 2.0 最新版》(MaxwellRender v2 )2.0[壓縮包],行業軟件、資源下載

- 《AMESim-國際最著名的工程系統高級建模和仿真平台》Rev 7.0A[ISO]

- 《Surpac Vision5.1B》(Surpac Vision5.1B)5.1_B[壓縮包]

- 《鴻業給排水8.0A破解版》(GPS8.0A)

- 《歐特克AutoCAD Sledgehammer 2011》(AutoCAD Sledgehammer 2011 for Mac)蘋果版RC2/Beta 6[壓縮包]

- 《自動PCB文檔編程》(DownStream Technologies Blueprint-PCB)v2.0.1.418-NULL[壓縮包]

- 《建築軟件》(DDS HOUSEPARTNER)V6.4[Bin]

免責聲明:本網站內容收集於互聯網,本站不承擔任何由於內容的合法性及健康性所引起的爭議和法律責任。如果侵犯了你的權益,請通知我們,我們會及時刪除相關內容,謝謝合作! 聯系信箱:[email protected]

Copyright © 電驢下載基地 All Rights Reserved